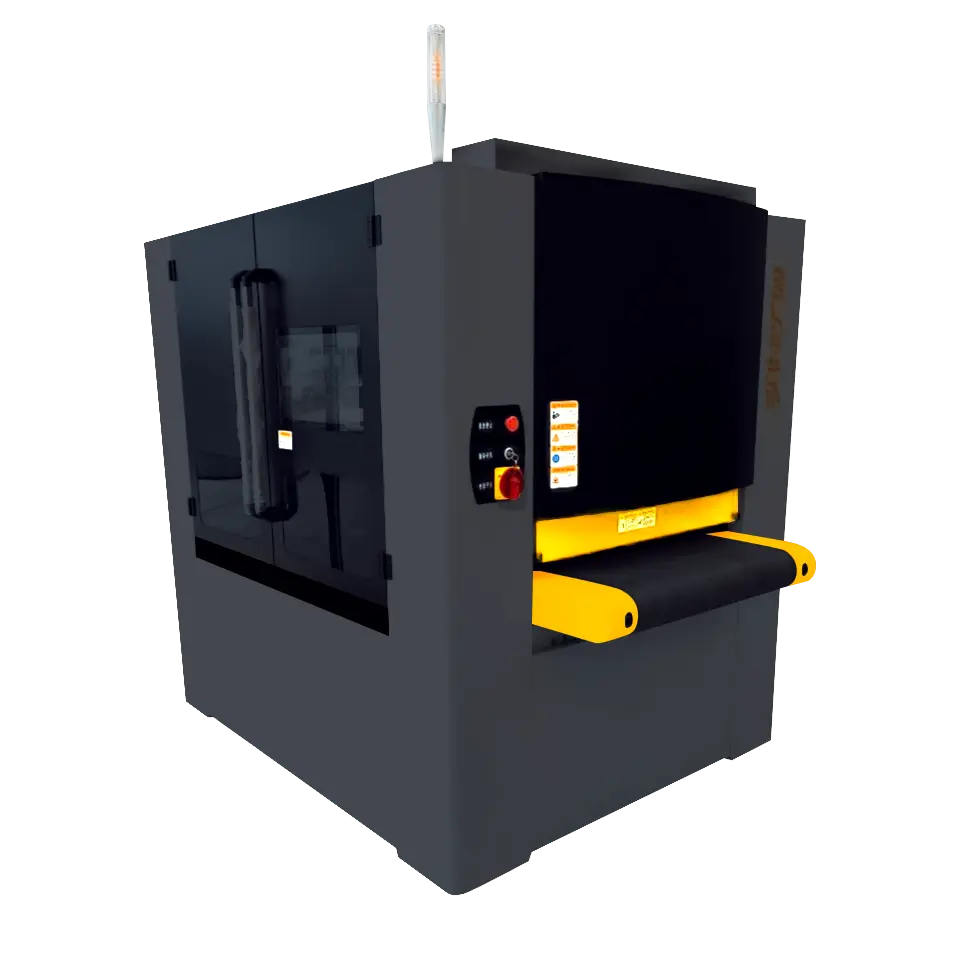

Lanuss LSP L Series

Sanding and Deburring Machine

The Lanuss LSP L Series are cutting-edge sanding and deburring machines designed to deliver precision and efficiency in metal surface finishing. With robust working widths, they easily handle a variety of material sizes, making them perfect for industries requiring consistent deburring, edge rounding, and sanding. The modular design offers flexible configurations to meet diverse finishing requirements, while the advanced dust extraction system ensures a cleaner and safer work environment.

These machines combine user-friendly operation with durable construction, providing reliable performance and superior results in every project. Whether you're streamlining your workflow or aiming for impeccable surface finishes, the Lanuss LSP L series are the ideal solution.

Everything you need

Variable Speed Control

Adjustable feed and roller speeds for optimized processing of different materials and surface conditions.

Robust Build Quality

Constructed with durable materials to ensure long-term reliability and consistent performance.

Modular Sanding Station

Equipped with multiple sanding and deburring stations, allowing for tailored surface finishing and edge rounding.

User-Friendly Interface

Intuitive control panel for easy operation and quick adjustments.

Versatility

Suitable for deburring, sanding, and edge rounding, making it ideal for a variety of industries including metal fabrication and manufacturing.

Improved Productivity

The wide working width and efficient operation reduce processing time, leading to faster project completion.

How it works

The equipment removes slag and burrs from the workpiece surface in a multi-step process:

- Abrasive Belt Station: Eliminates large burrs and remaining slag particles effectively.

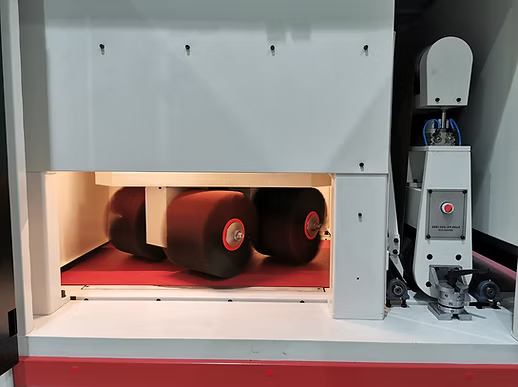

- Universal Sand Roller Brush System: Utilises four rotating sanding roller brushes to remove slag and refine edges and inner holes. The process ensures no burrs remain, maintains the accuracy of the workpiece edges, and achieves uniform R-angle rounding (customisable using different abrasive belts and processes). The dimensional integrity of the workpiece is preserved throughout..

Additionally, the abrasive belt station and sanding roller brush system can operate independently:

- The Abrasive Belt Station is ideal for processing metal hairlines, polishing, peeling, and slag removal.

- The Sanding Roller Brush System ensures 360° deburring, particularly for laser-cut and CNC-punched sheet metal parts with protective coatings. This system removes burrs without damaging the coating or scratching the surface, thanks to specially designed soft abrasive brushes that target burrs only.

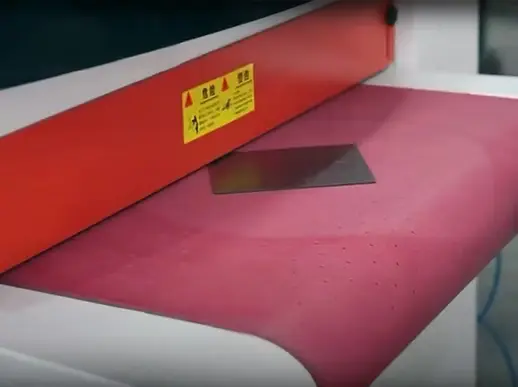

Conveying System

The equipment features a strong vacuum negative pressure adsorption system that securely holds workpieces over 50mm in size without additional tooling. For special workpieces, optional tooling can be used. The transmission system offers variable speed control for precise operation.

Dust and Safety Management

The machine includes a wet vacuum cleaner to minimise safety risks and efficiently manage grinding dust. A high-pressure, high-flow fan directs dust to a collection chamber, where it is captured through water spray deposition and filtered for environmental safety. Clean air is then discharged, ensuring a safe and clean working environment. The system also recycles and collects metal powder, supporting eco-friendly production practices.

SPECIFICATIONS

Working Width

≤ 800 -1600 mm

Min. Processing Size

50 x 50 mm

Processing Thickness

0.5 - 80 mm

Sand Rolling Brush Size

ф 300 x 300 - 550 mm

Belt Size

ф 1910 x 800 - 1600 mm

Sanding Belt Speed

12 m/s

Rolling Brush Rotation Speed

500 ~ 1400 rpm(adjustable)

Rolling Brush Orbital Speed

1 - 14 rpm (adjustable)

Number of Rolling Brush Revolving Shafts

1

Number of Rolling Brush Heads on Each Shaft

4- 8

Machining Thickness Servo Adjustment Precision

0.01 mm

Ventilation Capacity

4000 - 5000 m³/h

Machine Dimensions (L x W x H)

2700 - 4150 x 1810 - 2600 x 2170 - 2800 mm

Machine Weight (approx.)

3000 - 6000 kg

Voltage

380 V, 50Hz

Total Power

26.25 - 60.75 kW

Everything you need in field of machinery

Best Quality & Price

We have the excellent price-quality ratio.

Smart investments for long-term profitability

Lower investment, higher return.

Local Service and Support

Assembling as a service.

Need consultation?

Feel free to contact us! We are happy to serve and answer to your questions, its always absolute free

amm-e@amm-e.fi

+358 50 549 0432

Finland