Payapress 3 in 1 Busbar Machine HBC-A120

Busbar Bending Machine & Busbar Punching Machine & Busbar Cutting Machine

What is 3 in 1 Busbar Machine?

When it comes to busbar machines, HBC-A shines above all. This device is a full functioning 3 in 1 busbar machine that could fulfill all of your needs regarding busbar processing. In all three processes, the maximum busbar size that can be obtained is 12 × 120 mm. To explain more about this device the first thing that should be mentioned is that this device is equipped with 3 power packs which will give you the option to operate on all of the three sections which is punching, cutting and bending.

This means 3 operators could work simultaneously on the device without having any disruption. This busbar machine is the most popular device among other devices in our wide range of products and the reason is that it can handle all of the busbar processing levels such as cutting, punching and bending at the same time.

High precision plays a very important role on this device. With the help of programmable length stopper you will be able to get the finest and the most accurate results from each section. Also this device has been recently equipped with industry 4.0 which helps you with getting feedback from device at any time.

Modular Sanding Station

Equipped with multiple sanding and deburring stations, allowing for tailored surface finishing and edge rounding.

User-Friendly Interface

Intuitive control panel for easy operation and quick adjustments.

Versatility

Suitable for deburring, sanding, and edge rounding, making it ideal for a variety of industries including metal fabrication and manufacturing.

Variable Speed Control

Adjustable feed and roller speeds for optimized processing of different materials and surface conditions.

Robust Build Quality

Constructed with durable materials to ensure long-term reliability and consistent performance.

Improved Productivity

The wide working width and efficient operation reduce processing time, leading to faster project completion.

TECHNICAL INFORMATION

Busbar Processing Machine Features

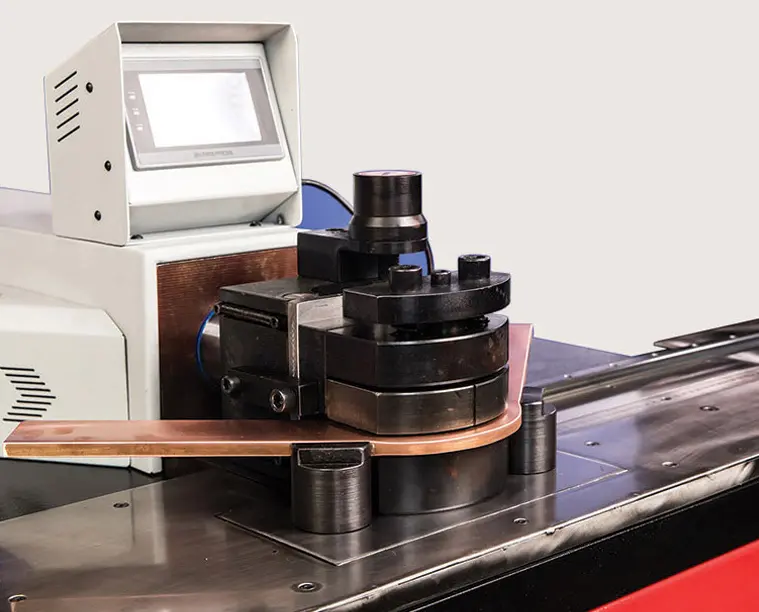

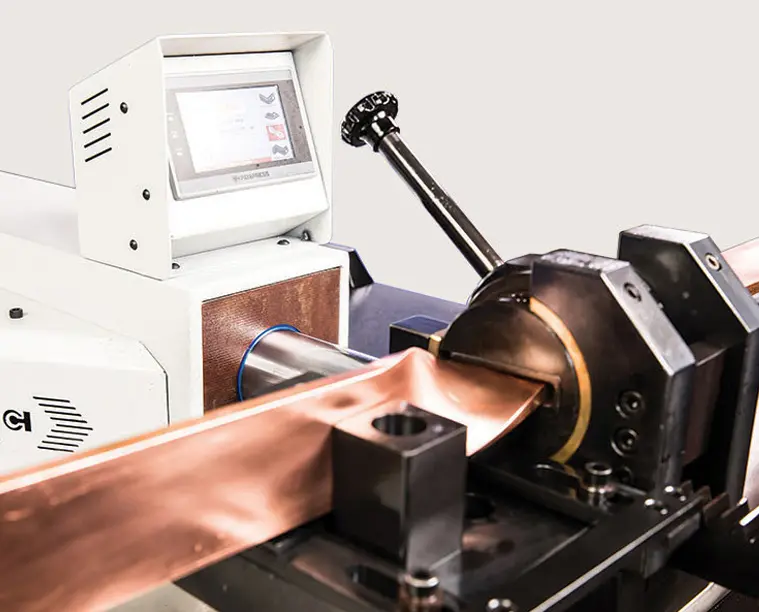

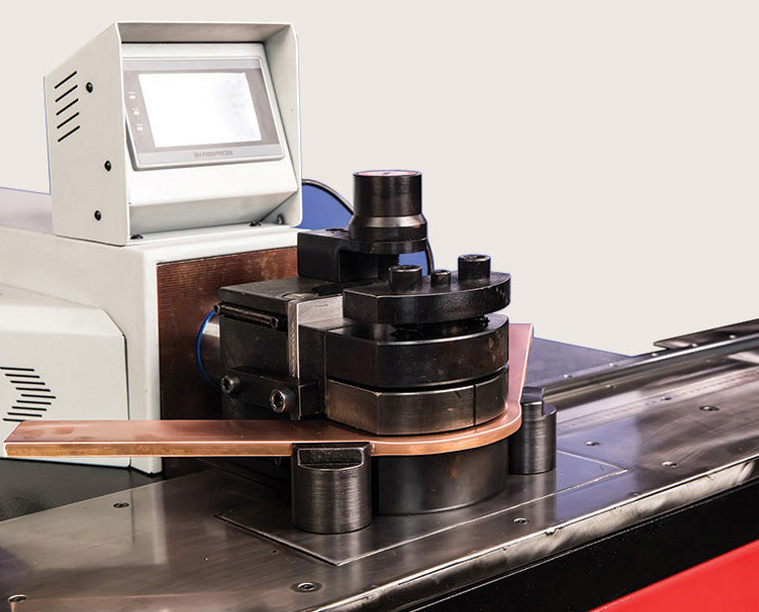

Bender

- Bender controller equipped with spring back compensation system.

- Digital angle indicator leads to perfect bending result.

- Rotatable plates prevent fractions in busbar surface

Step mold (Optional)

- To create too closed bends in one stroke

- could be designed in different sizes by order

Edge bending mold (optional)

- To bend busbars from edge side

- Busbar size limit: 40 × 10 mm

- Up to 90 degree and 50× 10 mm

- Up to 45 degree

Twist bending mold (Optional)

- To twist busbars for special purpose

- Busbar size limits: 60 × 10 mm

- Up to 90 degrees.

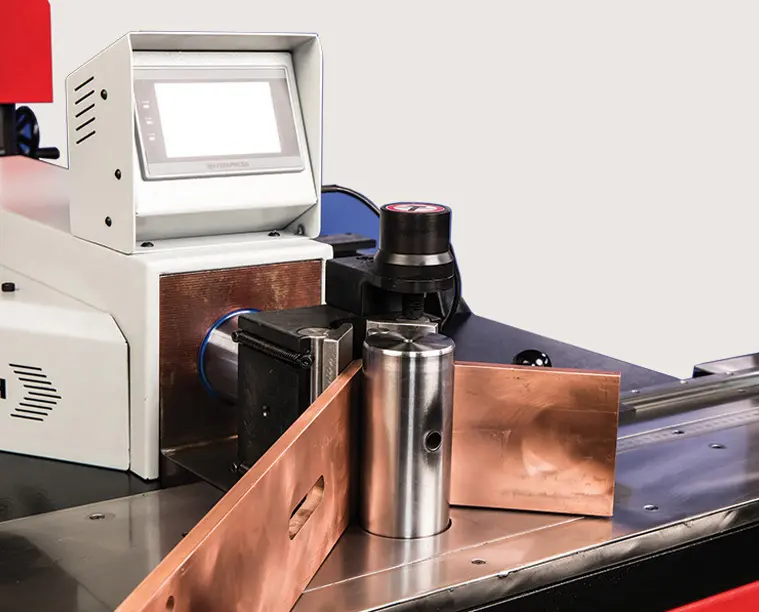

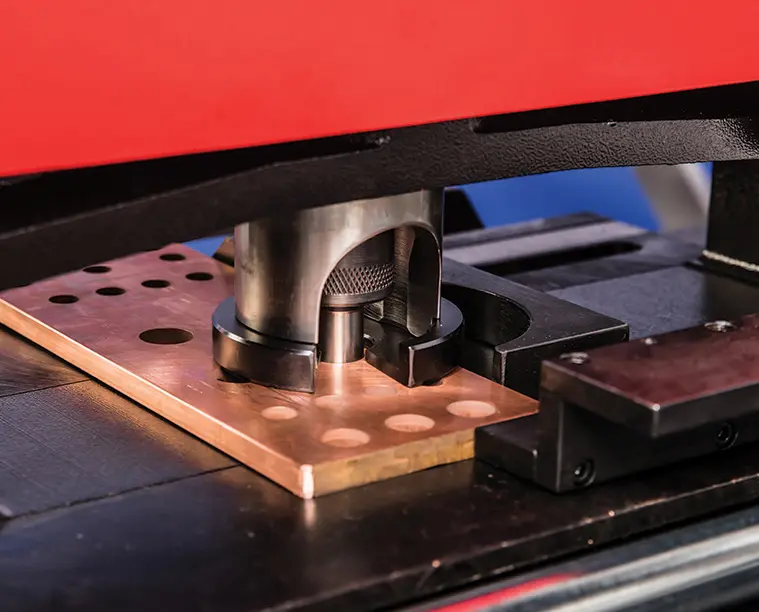

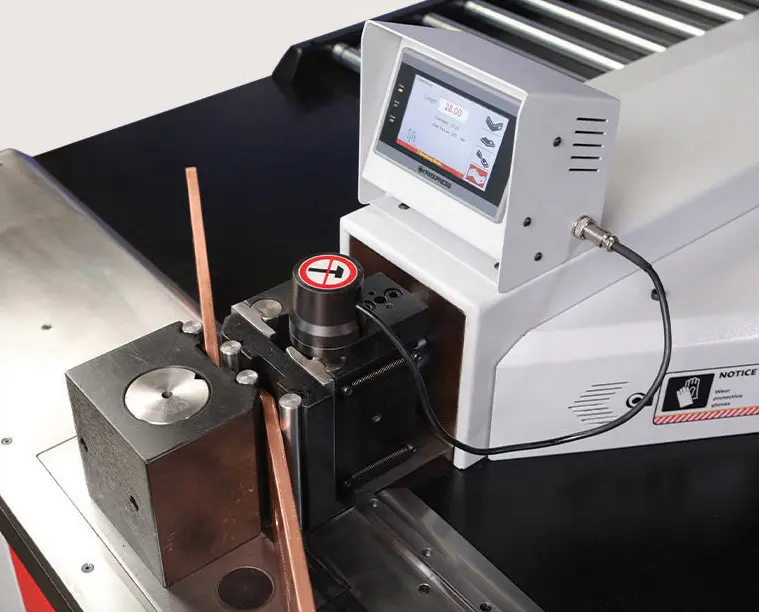

Puncher

Laser pointer helps to find the center of holes easily

- Easy and changeable dies

- Movable stripper plate prevents fraction in dies

- Double acting hydraulic system prevents sticking dies in busbar after punching

Guides could be moved up to center of dies

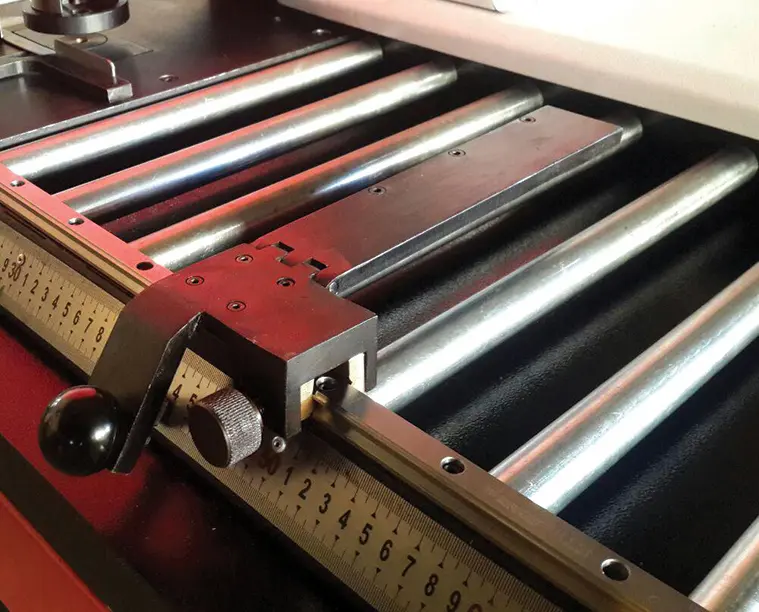

Rollers at two side of puncher for ease of busbar movement

Programmable Length Stopper cause high accuracy in positioning of holes (Optional)

- Could be programmed in absolute and incremental positions

- Programmable for 20 positions

- Handy Length stopper with high accuracy adjustment

- Circle dies from M6 up to M18

- Oval and rectangle dies (Optional)

Cutter

- Precise cutting with high quality

- Perfect finishing after cutting

- Center oriented guide leads to the best result

- Programmable Length Stopper cause high accuracy in positioning of cuts (Optional)

- Could be programmed in absolute and incremental positions

- Programmable for 20 positions

Rollers at two sides of cutter for ease of busbar movement

Handy Length Stopper with high accuracy adjustment

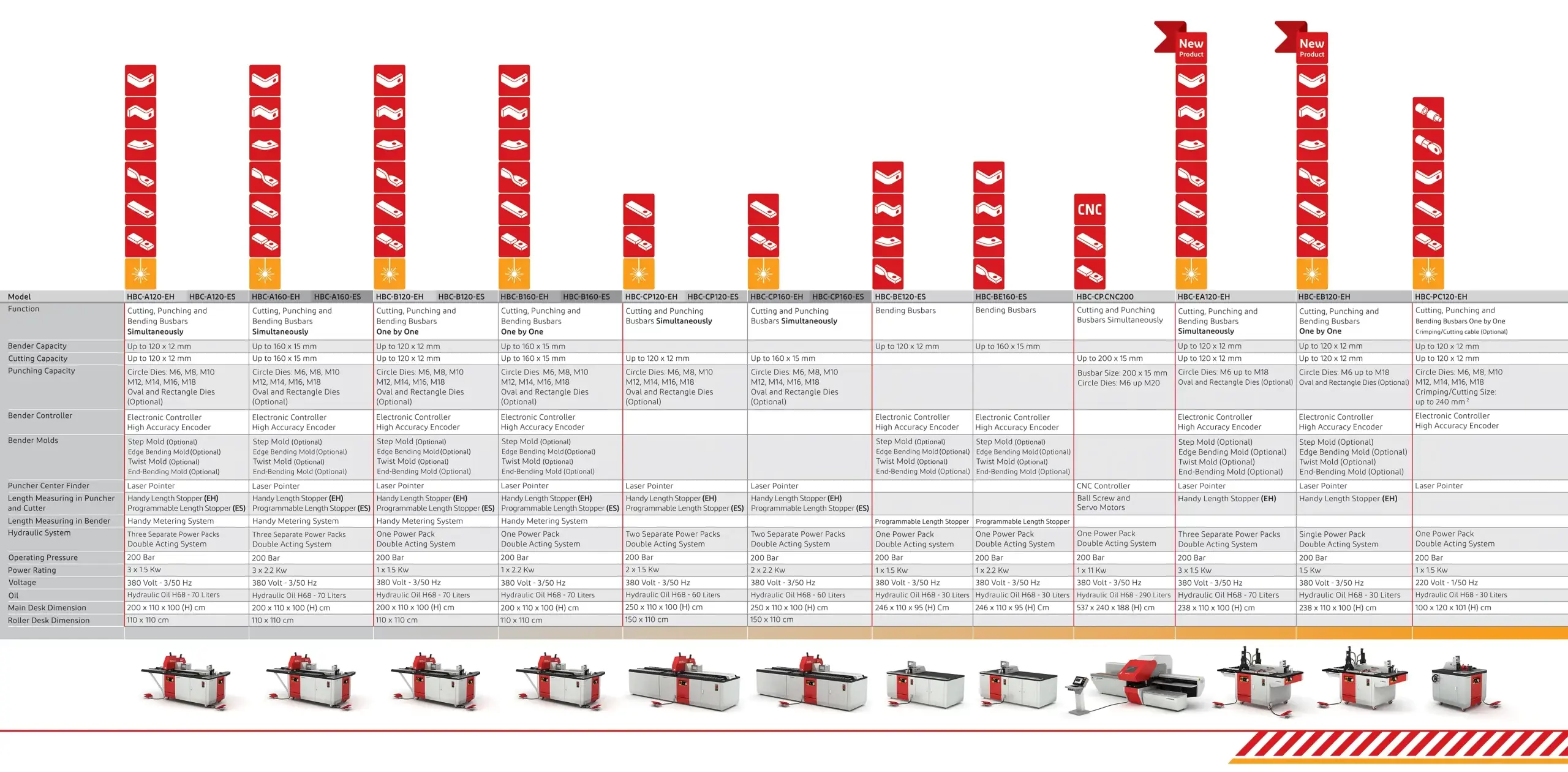

Specification

Function

Cutting ,Punching and Bending Busbars simultaneously

Bender capacity

Up to 120 x 12mm

Cutting capacity

Up to 120 x 12mm

Punching capacity

Circle dies: M6 up to M18 Oval and Rectangle Dies (Optional)

Bender controller

Electronic Controller, High Accuracy Encoder

Bender Molds

Step Mold (Optional), Edge Bending Mold (Optional), Twist Bending Mold (Optional), End-Bending Mold (Optional)

Puncher center finder

Laser Pointer

Length measuring in puncher and cutter

Handi Length Stopper (EH), Programmable Length Stopper (ES)

Hydraulic system

Three Separate Power Packs, Double Acting System

Operating pressure

200 Bar

Voltage

380 volt – 3/50 Hz

Power rating

3 x 1.5 Kw

Oil

Hydraulic Oil H68 – 70 Liters

Main desk dimension

200 x 110 x 100 (H) cm

Roller desk dimension

110 x 110 cm

Frequently asked questions

Here are some common questions about our machines.

All of the Payapress devices are equipped with “Siemens” motors.

Z-Shape bending die, Edge bending die, Narrow bending die, short leg bend mold which all are optional and can be made by customer’s order.

Circle dies are from M6 up to M18, Oval and rectangular dies are optional and can be made by the customer’s order.

HBC-A120 have the excellent price-quality ratio. It fulfill all of your needs regarding busbar processing. To get more information contact us through email, call us or leave a message on website, we will contact you ASAP.

We provide full support – from machine installation to operator training – ensuring a safe and efficient start to your production. We also take care of ongoing maintenance and supply any necessary spare parts.

Our delivery times are at least twice as fast as the competition – ensuring you get the machines you need without unnecessary delays.

Everything you need in field of machinery

Best Quality & Price

We have the excellent price-quality ratio.

Smart investments for long-term profitability

Lower investment, higher return.

Local Service and Support

Assembling as a service.

Need consultation?

Feel free to contact us! We are happy to serve and answer to your questions, its always absolute free.

amm-e@amm-e.fi

+358 50 549 0432

Finland