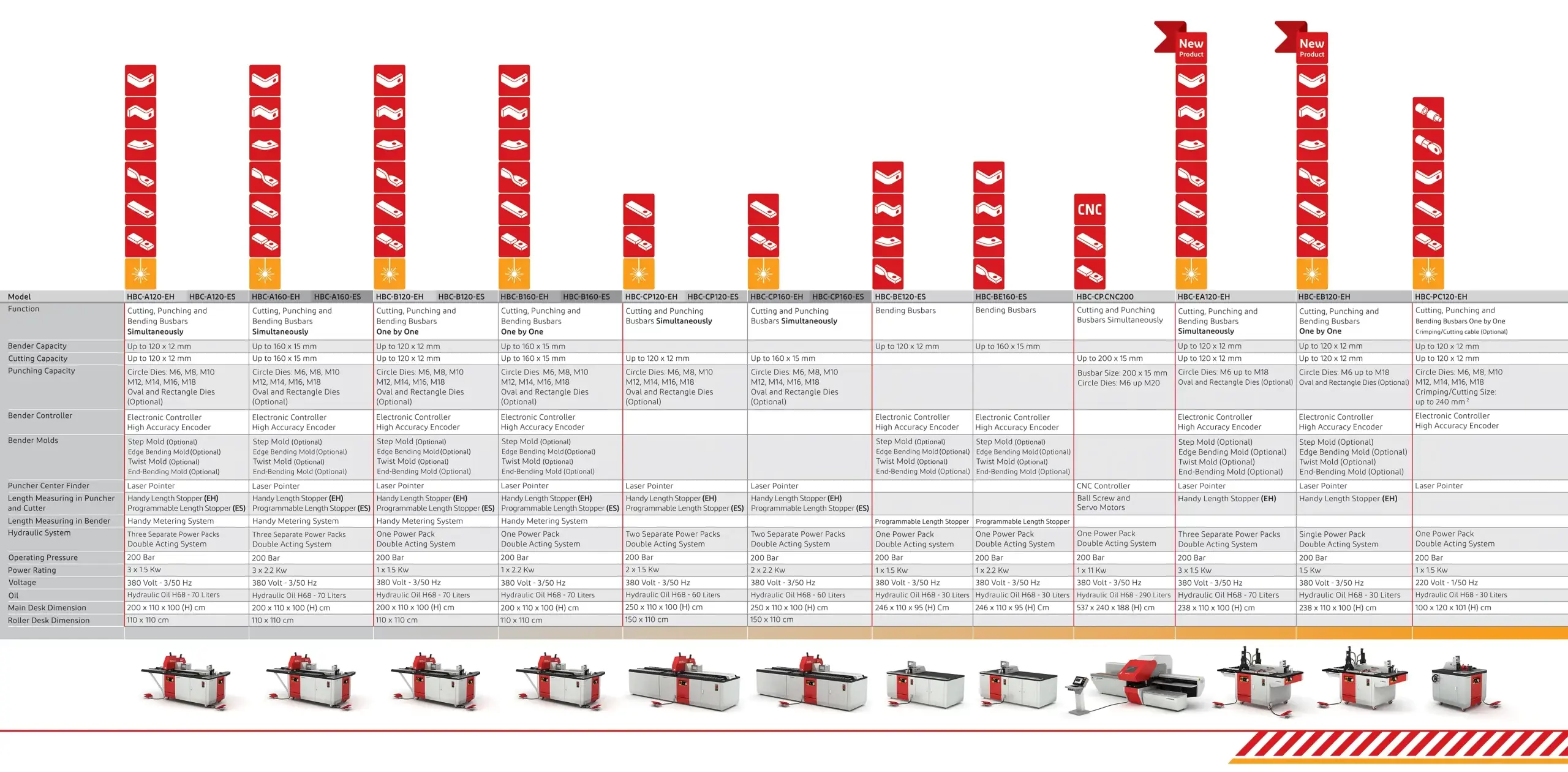

Payapress 3 in 1 Busbar Machine HBC-A160

Copper Busbar Machine - 3 in 1 Electrical Busbar Machine

Model: HBC-A160 ES/EH

3 in 1 Busbar Processing Machine

The most complete type of busbar machine is produced by Payapress company, which has all three processes of bending, cutting and punching simultaneously and with the utmost precision in compliance with the world’s standards. This device is equipped with a longitudinal digital ruler (linear encoder) in the bending section, which measures the displacement of the bending piston in each bending process is measured and by repeating it, you will be able to create bends of the same shape on the busbar. Also, this device is equipped with a spring back compensation system to create very precise bends. On the other hand, the cutting station of this device is equipped with center oriented guide that leads to the best result.

This device has the most purchase among Payapress devices specially in the Europe region, and the reason is that this machine is capable of doing all of the main three processes (punching, cutting, bending) up to 15 × 160 mm which is the standard size in Europe, without any disruption. The machine’s puncher station is equipped with a laser center finder (Laser Pointer) and, upon request, in machines equipped with programmable length stopper, it can be programmed (can be programmed in the X and Y axis in the puncher and can be programmed in the Y axis in the cutter).

This device model is equipped with three separate power packs which allows you to work on every station at the same time to get precise results in a short time.

This busbar machine is equipped with the 4.0 industry technology which makes the possibility of connecting to the internet and getting feedback from every process at any time of the device.

Modular Sanding Station

Equipped with multiple sanding and deburring stations, allowing for tailored surface finishing and edge rounding.

User-Friendly Interface

Intuitive control panel for easy operation and quick adjustments.

Versatility

Suitable for deburring, sanding, and edge rounding, making it ideal for a variety of industries including metal fabrication and manufacturing.

Variable Speed Control

Adjustable feed and roller speeds for optimized processing of different materials and surface conditions.

Robust Build Quality

Constructed with durable materials to ensure long-term reliability and consistent performance.

Improved Productivity

The wide working width and efficient operation reduce processing time, leading to faster project completion.

TECHNICAL INFORMATION

3 in 1 Busbar Machine Features

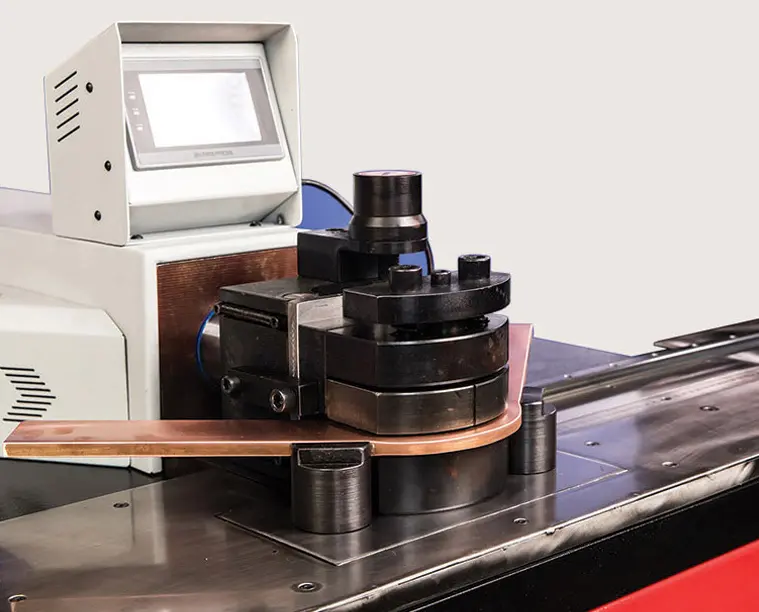

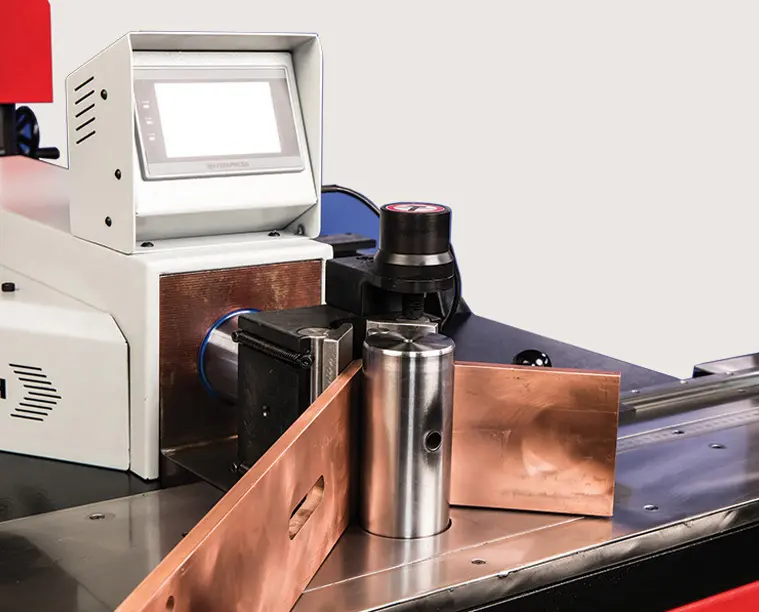

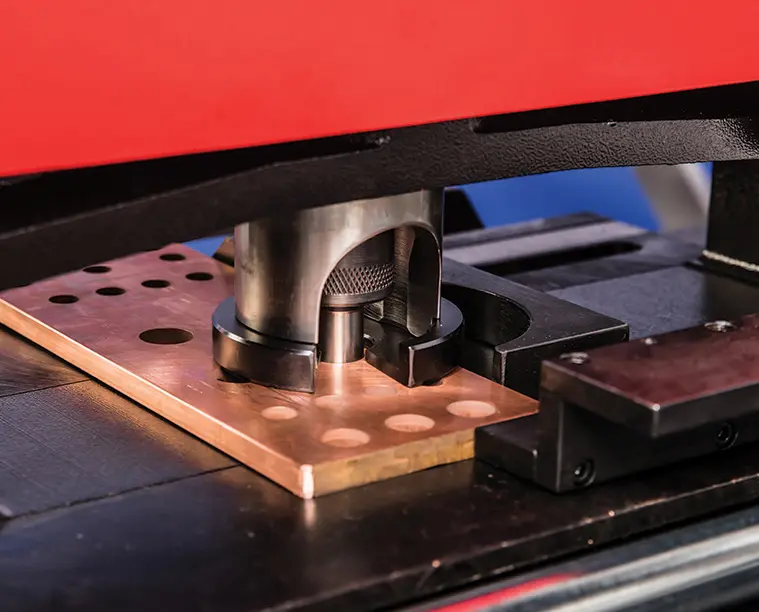

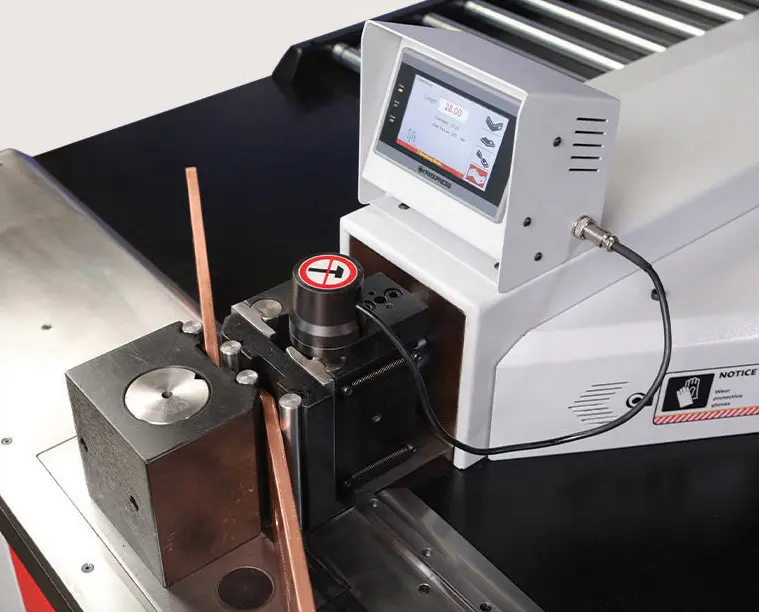

1- Copper puncher and cutter station of HBC-A160

The device in the puncher and cutter section is optionally equipped with programmable length stopper with the ability to save points required in a panel for the punching part along the X and Y axis as well as in the Y axis in the cutter station. Thus, by installing this option, there is no need to draw lines and points on copper busbars, also by reducing the operator’s intervention, human error in accuracy will be minimized. Also designing and manufacturing laser pointer in the puncher station of the device. increases the speed of the operation and the accuracy of the punching process, which the Payapress busbar processing machines have this capability along with the worldwide standards.

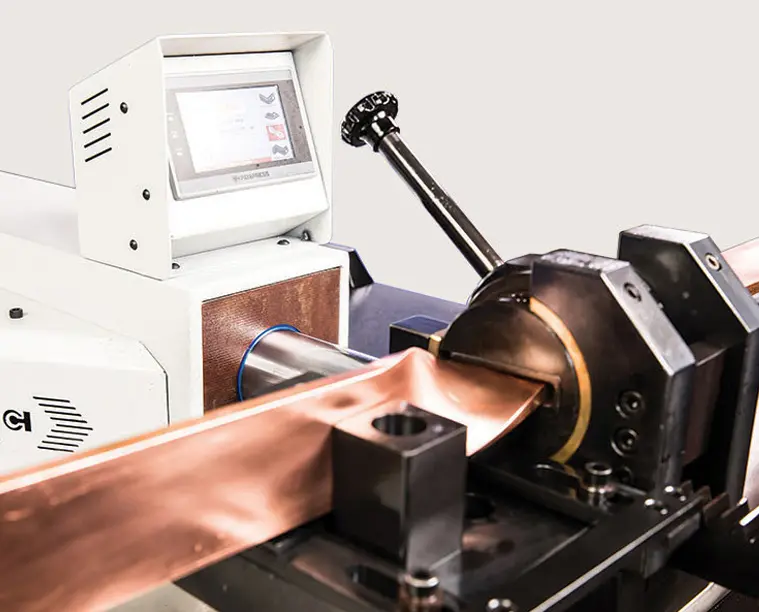

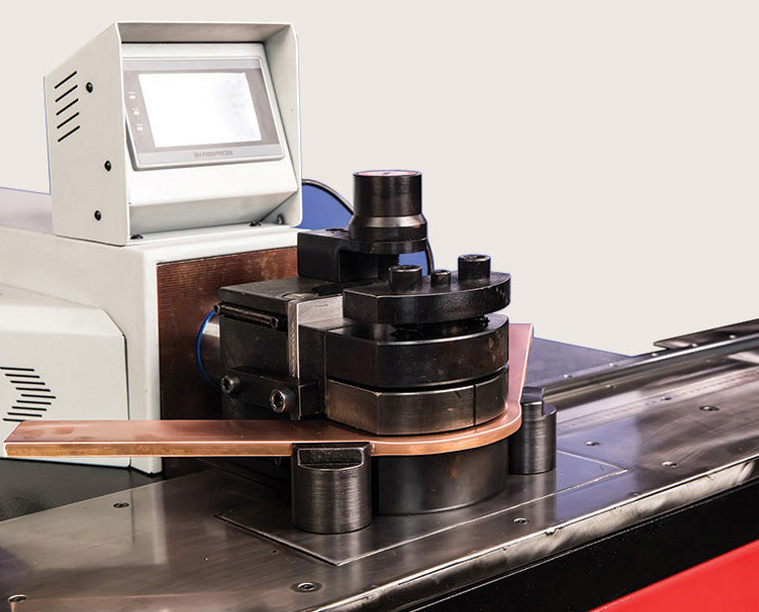

2- Bending Station

The bender of this device is equipped with two independent systems to achieve bending with high precision and repeatability to repeat bending process in a high number of times.

1-Rotary measuring system:

A rotary encoder with a pulse factor of 3600 pulses per revolution in couple is directly connected to the movable rotating plates of the bender.

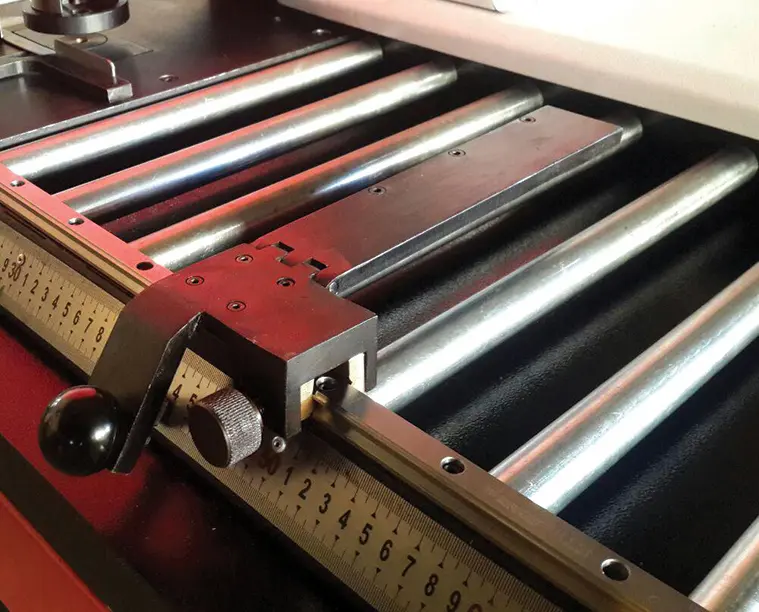

2-Linear measuring system:

A digital ruler consists of a magnetic strip and a digital receiver attached to the end of the piston rod measures and controls the advance rate of the piston in each bending process.

Specification

Function

Cutting ,Punching and Bending Busbars simultaneously

Bender capacity

Up to 160 x 15mm

Cutting capacity

Up to 160 x 15mm

Punching capacity

Circle dies: M6 up to M18 Oval and Rectangle Dies (Optional)

Bender controller

Electronic Controller, High Accuracy Encoder

Bender Molds

Step Mold (Optional), Edge Bending Mold (Optional), Twist Bending Mold (Optional), End-Bending Mold (Optional)

Puncher center finder

Laser Pointer

Length measuring in puncher and cutter

Handy length stopper (EH), Programmable length stopper (ES)

Hydraulic system

Three separate power packs, Double acting system

Operating pressure

200 Bar

Voltage

380 volt – 3/50 Hz

Power rating

3 x 1.5 Kw

Oil

Hydraulic Oil H68 – 70 Liters

Main desk dimension

200 x 110 x 100 (H) cm

Roller desk dimension

110 x 110 cm

Frequently asked questions

Here are some common questions about our machines.

This device is capable of processing busbars Up to 15 × 160 mm

HBC-A120 have the excellent price-quality ratio. It fulfill all of your needs regarding busbar processing. To get more information contact us through email, call us or leave a message on website, we will contact you ASAP.

We provide full support – from machine installation to operator training – ensuring a safe and efficient start to your production. We also take care of ongoing maintenance and supply any necessary spare parts.

Our delivery times are at least twice as fast as the competition – ensuring you get the machines you need without unnecessary delays.

Everything you need in field of machinery

Best Quality & Price

We have the excellent price-quality ratio.

Smart investments for long-term profitability

Lower investment, higher return.

Local Service and Support

Assembling as a service.

Need consultation?

Feel free to contact us! We are happy to serve and answer to your questions, its always absolute free.

amm-e@amm-e.fi

+358 50 549 0432

Finland